Most woodworkers don’t give much thought to most basic tools in their shop, they are too busy picking out the best chisels, scrapers, clamps, special jigs, tools, woodworking machinery, hand planes, and all manner of accessories to make their work go smoothly and more accurate.

What they are missing is the measuring and marking tools.

Look at what you own in the way of measuring and marking tools. Many of the frequent troubles in woodworking are out of four-sided figure frames, casework, joints that fit poorly, etc. can be traced back to the measuring and marking mistakes. The culprit is usually only a matter of using the incorrect measuring and marking too for the job. A tape measure was not calculated for the extremely accurate measurements that most woodworking projects require.

Making for some exacting work, in most woodworking projects, the first thing you do is mark and measure linear dimensions. Miscalculations as small as 100th of an inch when marking and measuring in such complicated joinery or small, tight parts will later show up as gaps in joints or uneven parts or a host of other less-than-perfect results.

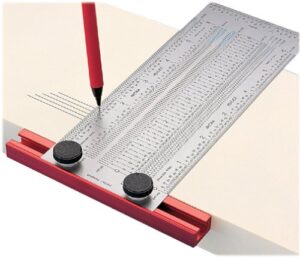

Depending on how correctly you are able to interpret a measurement into an objective mark on a piece of wood is the outcome of measuring from point 1 to point 2. Holding down a tape measure while trying to accurately mark off a measurement is a difficult task, mainly because tape measures are not meant to lay flat. An accurately calibrated and readable marking and measuring tool is needed for all woodworking projects.

Since even the best measuring tools are relatively inexpensive, most woodworkers acquire a variety of rules and tape measure to meet different needs. However, it is advisable to use the same rule or measuring tool throughout the project, just in case there is any variation between one tool and another.

Purchase both rules and tape measures with standard and metric graduations – but take care not to confuse one system with the other once you have begun to mark out a workpiece. You can measure one piece of wood accurately and then use it as a template for the other pieces if more than one of the same size is needed, this will save you time in the marking and measuring department.

Rules And Measures

Tape measure – retractable steel tapes, measuring from 6 to 16 ft (2 to 5m) long, are usually graduated along both edges. A lock button prevents the tape from retracting automatically. Some tape measures incorporate a liquid-crystal display that tells you how far the tape had been pulled from its case; a built-in memory retains the measurements when the tape is retracted. Self-adhesive steel tapes are sold without cases sticking along the front edge of a workbench.

Four-fold rule – The folding carpenter’s rule made from boxwood with brass hinges and end capes is still popular among traditional artist. Most folding rules are 3ft (1m) in length and fully extended. Because it is relatively thick, you have to stand a wooden rule on edge in order to transfer measurements accurately to the work. Similar rules made from plastic are sometimes made with beveled edges to overcome this problem.

Straightedge – every workshop needs at least one sturdy metal straightedge, measuring between 1ft 8in (500mm) and 6ft 6in (2m) long. A beveled straightedge is ideal for making accurate cuts with a marking knife and for checking that a planed surface is perfectly flat. Some straightedges are etched with standard metric and/or graduations.

Squares and T-Bevels

Squares are used to make sure things are at a right angle to one another. In a woodshop, these things might be the edge of a board, the shoulder of a Tenon, the fence on a jointer, and so on.

However, square is an abstract term. Looking at closely enough, nothing is truly square; some things just approach the idea of being square than others. There are three types of squares generally used in woodworking.

Try squares – are the most commonly used squares among furniture makers. They have blades of brass or steel (generally from 6in to 12in long) set in a thicker wood or metal stock. If the stock is wood, it should be faced with metal to ensure long-term accuracy. The reliability of try squares can vary sharply, even among those made by the same manufacturer.

Engineer’s square – these are similar in design to the try squares, but made entirely of steel. Blades lengths start at approximately 2 in. these squares are more reliable than try squares, probably because engineers are a more demanding bunch than woodworkers. Engineer’s squares can be used interchangeably with try squares in a woodshop.

Framing squares – these are made for house building. They have two large blades that form a right angle. One blade is 2in wide by 24in long; the other is 1 ½ in by 18in long. Framing squares are not expected to be precise as try squares or engineer’s squares.

Marking tools

Pencils – every shop needs pencils for marking out your designs and marking wood in order to keep track of jointed surfaces and which piece fits together where.

Knives – these are indispensable in a woodshop for tasks such as marking Tenon shoulders and cutting cardboard templates. Knives are a preference, pocket knives, box cutters; utility knives with a retractable blade are all useful in a woodworking shop.

Awls – these are sharp, pointed instruments with a variety of uses. They differ in the fineness of their points and the thickness of their shafts. A fine-pointed awl is useful for marking out joinery and scribing lines and a thick-shanked, broad-pointed awl is good for making pilot holes in wood prior to drilling. The dimple it leaves when tapped with mallet forms an exact starting point for a drill bit.